Do you like doing fun DIY projects but often face problems operating power tools? Well, if your tools aren`t working, there’s a high probability that it has something to do with the carbon brushes. So, if you own a set of useful power tools, you should check out a range of carbon brushes at topdealsonline.shop to avoid any potential power tool problem.

Now, there are two main types of tools: brushed and non-brushed. For this article, we will stick to brushed tools and the importance of carbon brushes.

What Are Carbon Brushes?

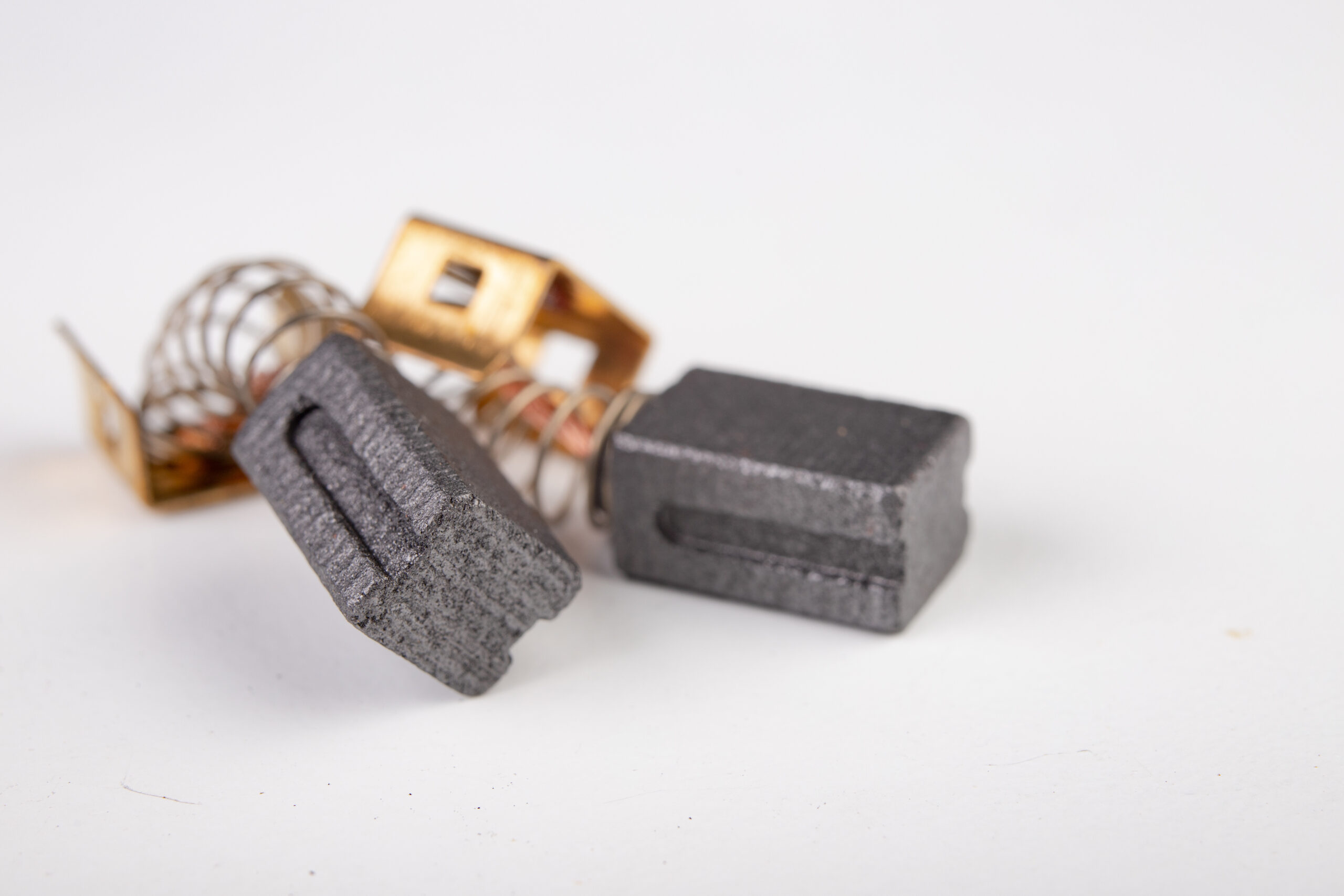

Carbon brushes look just like a traditional bristled brush, but they have an essential role in operating a power tool. In most cases, carbon brushes are part of electric motors. Their objective is to deliver electricity by staying in contact with the revolving portion of the motor.

Carbon brushes are usually made from low-friction conduction carbon materials such as cooper graphite, electro graphite, and pitch bonded carbon. Some carbon brushes also contain natural graphite, silver graphite and resin bonded carbon.

How Can Carbon Brushes Help?

When your power tools are not able to fulfill your DIY or other professional requirements, they may need a carbon brush replacement. The role of a carbon brush is much more than maintaining electricity contact in a power tool rotation. In simple terms, carbon brushes reduce the damage and wear and tear of your power tools. They carry the current back and forth from the stationary parts of a motor to the moving parts.

Carbon brushes may wear down during the process as a result of friction, but they do protect your power tools from the same. You don`t have to worry about this wear and tear because the alternative would be the wearing down of the commutator, which is the ring the carbon brush presses against. Because the brushes are designed to gradually wear and tear, carbon brushes succumb to heavy usage and long hour operations of different power tools.

Consider carbon brushes as the backbone of your power tools because they act as a bridge for your power tools to work at their optimum level. They get the job done despite being small in size, easily replaceable, and prone to excessive wear and tear. Carbon brushes are designed in a way that makes them easily replaceable. Initially, when you use a carbon brush, they may not fit perfectly, but over time, your brush will fit effortlessly against the commutator ring.

When to Replace the Brushes in Your Power Tools?

When you operate different power tools, you might encounter certain hindrances. At first, it might be tough or even seemingly impossible to determine what`s wrong with your power tools. But if it`s a carbon brush problem, there are a few indicators to help you out. Here are some of them:

- Bad smell

- Poor performance

- Sparking

- Malfunction

- Burning

- Stalling

- Cutting out

- Crumbling

If you feel like that your power tool is not performing up to the mark, it`s better to replace the carbon brush as soon as you can because a delay might cause multiple disruptions in your power tool. And if you’re still not sure whether your power tools require a carbon brush replacement, below are some great tips to keep in mind:

- Try to look through the tool into the power tool brush and evaluate its outlook. A wholly worn carbon brush is easily discernible at a glance. A general rule implies that if a brush has worn out about a quarter-inch long, you need to go for a replacement.

- If you’re a professional working with power tools, you may get reimbursed for replacing carbon brushes. But if you do it for fun, you can`t afford to get a carbon brush replacement after every project. Therefore, you have to monitor the performance of your power tool and, subsequently, its carbon brushes. You can even increase their life and keep them safe, which would prevent the wear and tear.

- It’s also essential to look at the carbon brush spring. For instance, if there’s a broken lead or the spring has collapsed, it warrants a replacement. Remember, if you delay replacement and keep using a worn-out brush for too long, it can destroy the commutator ring or an armature, which the brush makes contact with.

- A minor replacement delay can render your power tool completely ineffective. It’s perhaps needless to say that replacing an armature, ring, or the whole power tool will be much more expensive than a small functional carbon brush.

You have to keep a constant check on your brushes by monitoring their performance and usage with different power tools. You can do the same by operating your power tools in various capacities. It`s not necessary to operate them at full capacity all the time as it can extend the life of your tools and their installed carbon brushes.

How To Maintain Your Carbon Brushes?

There are some recommended practices to maintain your carbon brushes, saving you from replacing them too frequently. Check out these tips to help you keep your brushes in great condition:

- Check for any dirt or damage on the carbon brushes.

- Check if the brush can easily move within the motor and their inherent contact with the commutator ring.

- Check for springs and apply pressure adjustments, if needed.

- Check for distance and deviations between the commutators.

- Check for any blackened or burned areas in the commutator.

- Evaluate the bearing size and make sure that they do not cause excessive vibration.

- Evaluate the roundness of the carbon brushes.

When you finally reach the stage of replacing your carbon brushes, you need to look at the specifications because a minor change in the composition of a carbon brush can damage your power tool. In a nutshell, you should look for design, friction resistance, abrasion, electrical conductivity, size, and overall resistive power before replacing a carbon brush.

Key Takeaway

Not all people understand the function and uses of carbon brushes because of their size and invisibility. But as this article demonstrates, carbon brushes are one of the most crucial components of any power tool. Remember, without brushes, your generators, motors, and other tools won`t be able to conduct electricity, which can effectively render your power tool useless.

If you want to preserve and protect your power tools, make sure that you’re practicing regular maintenance checks on your carbon brushes. This task will require time and effort but this is important to ensure that your carbon brushes remain functional for the longest possible time.