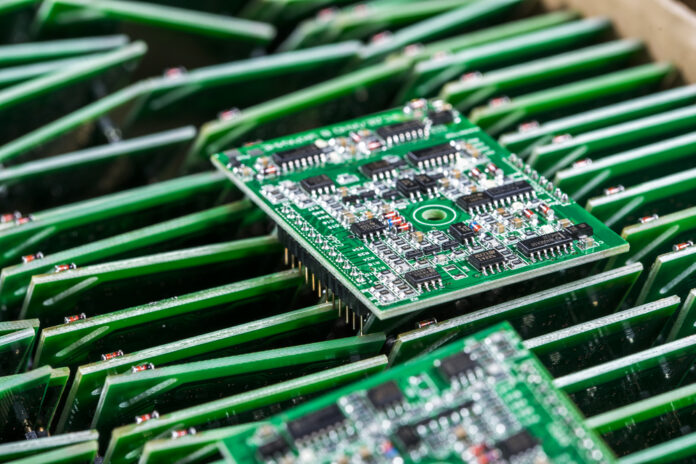

PCB: A well-known acronym in our daily life……But, do you know what exactly is it and why we need to assemble it? If No, this article will lead you to get the perfect solution for these queries.

In simpler words, PCB is a term being used for Printed Circuit Board where different electrical and electronic components are being arranged in a particular manner to decrease the complexity of operations. PCB is one of the most critical parts of various electronic equipments such as pagers, radios, radars, computer systems, mobile phones, and even satellites as well whereas it serves as a base to support for wiring area being mounted on its surface. The PCBs are most commonly compose from fiberglass, composite epoxy, or another composite material that improves its working capacity and respond in favor of electronic gadgets.

Why is it necessary to assemble PCB?

Before going further with the article, it would be quite beneficial for everyone to know what exactly the need of PCB assembly is. The design is one of the significant aspects of any PCB that plays a vital role in deciding its cost and success rate. A minor change in the basic designing of PCB may affect the results both positively and negatively as well. As we know that everything in a circuit board comes up in different packages, so that it gets essential to assemble it productively so that to extract out best results from it.

Rules to follow during PCB Assembly

When it comes of starting up with a new design or assembly process, it gets essential to carefully develop a specific set of rules so that to avoid the chances of getting any failure at any stage of it. Extracted from one of the leading PCB Manufacture and Assembly company, www.Raypcb.com, here is the list of some rules that will help you in creating a design with extreme reliability and functionality for you.

Reduce the complexity: Complexity in design is one of the major causes that makes it very much difficult to assemble and hence increases the chances of having errors in it as well. It is one of the primary reason of being getting out of cost most of the times. So make use of standard components with Low-Volume PCB Assembly in your design and also try to reduce the number of elements over there. Try to make use of components with multiple function option that will help you in eliminating the extra one conveniently.

Easy installation: Design the PCB that requires less processing and least installation steps to follow. It will not only make the installation process convenient for you but saves much of your labor and time as well.

Use components with high placement tolerances: While working on the assembly process of PCB try to use the parts with high-level placement tolerance. It will not only help you in reducing the general errors being occurred during the installation process of components. Lesser will be the error rate, lesser will be the chances for being getting failed at any stage of working.

Moreover, you also need to avoid the usage of tomb-stoning instances in your PCB design.

Create a modular design: Try to create a modular design PCB with multiple functional blocks. It will not only help you in using the PCB in different products but also helps in reducing its complexity and hence the cost evolved as well. Modular PCBs gets very helpful in especially when being tested or being repaired in the future, after all simpler systems are easy to check and fix.

Use basic mounting techniques: It is another one of the most impactful ways of creating a cost-efficient PCB design for your products. Fasteners are in great trend these days. These are the devices generally used for mounting components on PCB. But making use of such devices raises the costs of PCB to a great extent. You can make use of powerful integrated circuits to integrate heat sinking into the PCB design is very impactful and cost-effective manner.

Reduce assembly directions: While working on the assembly process of PCB try to make as simple as that. The top-down design is one of the most commonly used and easiest way to assemble the components on PCB. Making use of a single-sided assembly process not only help the users in saving much of your time during the installation process but also makes it easy to turn or rotate it whenever it is required. Moreover, try to remove the repositioning or re-handling situations so that to make it convenient by user side.