Concrete is perhaps the most commonly used construction commodity in the world. Instead of being an autonomous material, concrete is a mixture of different components such as water, cement, gravel, and fine aggregate. Sand and gravel are types of fine aggregates and rough aggregates, respectively.

Why is concrete important?

All construction companies catering to the commercial market use concrete. But why is concrete a vital material for the construction industry?

Concrete is just like mortar in both its structure and its composition. Such connection implies that concrete acts as a foundational material for the different masonry elements in building, as with mortar. As opposed to regular mortar, concrete has a variety of uses, and this flexibility is because both fine and coarse aggregates are made of concrete. The broad scale of the coarse aggregates provides the concrete endurance properties that mortar does not possess. It renders this ideal for more significant buildings, whereas most mortars use sand as the primary filler and are therefore weaker than concrete.

What are the most common types of concrete?

Ready-mix concrete

Ready-mixed concrete is concrete made in a plant and then transported to the worksite by vehicles comprising in-transit mixers. It is carried out under standardized procedures and trucked and deposited at locations using highly advanced vehicles and approaches. It ensures that the specialized concrete formulations already developed should only need to be poured on the site of construction.

Volumetric concrete

Volumetric concrete is a substitute to ready-to-mix concrete to address curing concrete for longer distances between the plant and the building site. Upon blending, it is essential to preserve the correct moisture and temperatures to keep it in a usable state. Volumetric concrete uses specialized vehicles such as volumetric mobile mixers that hold the materials and the water to be combined at the building site. To remove any transportation complications that may affect the pre-mixed concrete and render it useless.

Decorative concrete

Decorative concrete is a concrete type that has been processed in several ways to improve its artistic appeal. For example, it can go through procedures such as dyeing, texturing, moulding, polishing, adding decors, and many more. Different products are used in the manufacture of decorative concrete, including colour hardeners that provide a unique shade and a durable surface that can be used for any application.

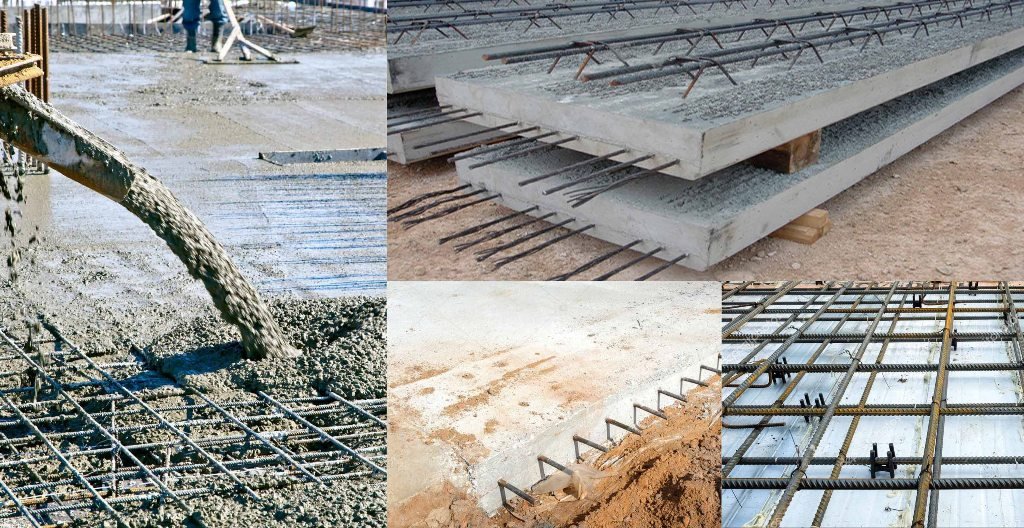

Reinforced concrete

Reinforced concrete is a concrete type that passes through reinforcement, granting it the resilience to endure intense compressive stress. Plain concrete is fine for compression, but it appears to lack compressive strength. In the meantime, reinforced concrete provides a mix of both characteristics: substantial strength and tensile stress capacity. It is made of steel with steel fibres, rods, mesh, and bars. During reinforcement, it is crucial to create a close connection between both the concrete and the reinforced metal that would decide the quality and durability of the resulting concrete.

Prestressed concrete

Prestressed concrete is a specific type of concrete that passes through a prestressing process to get the ideal structure. Before final deployment, concrete tendons and bars are prestressed throughout processing and application. Concrete bars are fixed from the ends and sealed, and as long as they are reinforced, they are compressed. Through this, the bottom section of the concrete bars is strengthened to handle the pressure. As the prestressing phase involves heavy machinery and technical expertise, it is performed on location.

Ask all the construction companies out there, and they will inform you of the same thing – that concrete is a critical component in every infrastructure project. If you need concrete for your next project, contact a professional contractor now. They will know what will fit your needs best.